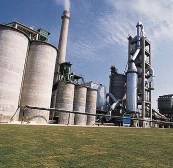

We Manufacture all type of cement plants, Cement manufacturing is A process includes multiple stages, Ashoka’s Cement Plant division holds the deep knowledege of all type of cement plant processes related to raw material to final bags production.

We delivers best quality cement projects most reliable, cost effective, energy savings and provide best cement, We have supplied and installed various cement plant projects in India, golf countries, south africa. Our heighly qualified and experienced engineers and technical designers and consultants dedicated with client’s requirement to give best architecture plant design, fabrication and construct all the required conditions for the plant installation.

Ashoka Group is the bigger manufacturers and exporters of the cement plants equipments. The objective of cement plants equipments is to improve the product quality. The raw material used in cement plants are sand, clay, limestone, shale, and iron ore. Cement plants require areas where infrastructure rehabilitation is necessary.

Our Extensive Services Includes:

- Feasibility Study and Project Reports

- Detailed Engineering of Projects & Equipments

- Equipment Design and Promotion Drawings

- Complete Integration

- In House Application Engineering

- Expansion / Modernization for increasing the capacity

- Erection and commissioning

Cement Plants | Steel Re-Rolling Mills | Sponge Iron Plants

Send Business Enquiry | Contact Us