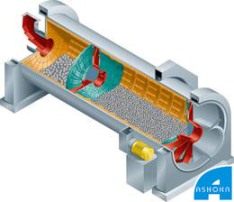

Tube Mill Internal

The tube mill internals of cement manufacturing industry is composed of the grinding media, shell liners and the diaphragm. The change in impact condition may result in either spalling or hardening of the grinding media which in turn decrease the shelf life, increase the operating cost and increase the downtime. An effective shell liner can result in optimum consumption of power and also productivity. The shell liners are available in either boltless or bolted design according to the Non DIN or DIN standard pattern of shell drilling. The diaphragms are the form of mechanical assemblies that are designed to partition various portions of the mill. Apart from this function, diaphragms are meant to carry out carious other functions like leveling the material in upstream chamber and optimization of the mill ventilation.

The diaphragms can be classified into four types:

• Transfer diaphragms: The transfer diaphragms are situated between the grinding chamber and drying chamber. This type is present in raw mills like birotator mills, monochamber and airswept.

• Intermediate diaphragms: The intermediate diaphragm is present between the grinding compartments. This type is present in three chamber mills and two chamber mills.

• Central discharge diaphragms: The central discharge diaphragms are present between the grinding chambers. This type is present in birotator mills.

• Outlet Diaphragms: The outlet diaphragm is located at the mill discharge. This type is present in three chamber mills, two chamber mills and monochamber mills.

The transfer diaphragms should permit optimum passage of gas to decrease the drop of pressure. It should be resistant towards very high temperatures. It should be compatible to all deformations in shell. It should possess good resistance to axial forces.

The intermediate diaphragm is further subdivided into three types:

• Flow control Diaphragm

• Double Diaphragm

• Single Diaphragm

The rate of wear of the intermediate diaphragm completely depends on the nature of the material that needs to be grounded and also its impact. In case of discharge diaphragms, wear occurs due to the friction forces existing between grinding media, grate plates and ground material. The grate plates present in the intermediate diaphragm is more delicate structure in the ball mill on wear point of discussion.

For More details about Cement Plant Equipments & Other Mills Projects, Budget, Machines, AMC, Up-gradation etc, Please contact Us @ +91 9811141400 or Send Business Query